External Concrete Vibrators: Efficiency and Precision in Compaction

Proper concrete compaction is essential to ensure the strength, durability, and surface finish of any structure. While internal vibrators are the most commonly used solution, there are situations where they are not feasible. In such cases, external vibrators become the ideal alternative.

When to Use an External Vibrator

External vibrators are particularly useful in the following scenarios:

- Dense reinforcement or complex shapes that prevent the use of internal vibrators.

- Low sections or narrow openings where access is limited.

- High-quality surface finishes with no visible defects.

- Precast elements, such as molds or silos.

- Wall heights beyond the reach of internal vibration.

- Heavily reinforced areas requiring uniform vibration distribution.

What You Need to Know Beforehand

Before selecting the right equipment, it’s important to consider:

- The type of product to be manufactured and the characteristics of the concrete.

- The design and material of the molds.

- Whether the molds can be equipped with external vibrators.

- The total weight to be vibrated (mold + concrete + reinforcement).

- Technical drawings or sketches of the molds for proper planning.

- Whether internal, external, or combined vibration will be used.

3000 rpm vs 6000 rpm: Choosing the Right Frequency

The speed at which the vibrator’s eccentric weights rotate (rpm) directly affects the quality of the vibration:

- 3000 rpm: suitable for standard applications. VET/VEM: view product

- 6000 rpm: produces a smoother, more fluid vibration—ideal for delicate molds or high-finish requirements. These models require a frequency converter for operation. VEAF: view product

The choice depends on the type of concrete, mold geometry, and the desired surface finish.

Available Ranges and Adjustable Centrifugal Force

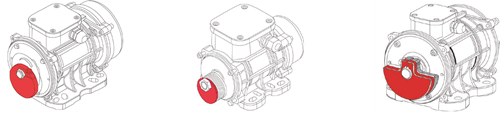

All ENAR external vibrators allow the centrifugal force to be adjusted to suit different needs. By removing the side covers, you can access the eccentric weights and offset them to modify the force.

- Solid round eccentric

- Removable eccentric

- Half-moon solid eccentric

⚠️ Important: Eccentrics must be adjusted equally on both sides of the vibrator to ensure balanced operation.

Best Practices for Installation

- Optimal vibration time: between 2 and 3 minutes. Preliminary testing is recommended. If possible, observe the concrete—vibration should stop when air bubbles disappear and the surface becomes shiny and smooth.

- Vibration reach: between 0.9 m and 1.5 m radius around the vibrator.

- Efficient distribution: it’s better to use several lower-power vibrators than one high-power unit to achieve better coverage and finish.

- Minimum coverage: ensure at least the first row of vibrators is fully covered.

- Combining internal and external vibration: always start with internal vibration, then follow with external.

- Mounting: clamps should be fixed to the ribs of the formwork, where the structure is strongest.

Conclusion

External vibrators are a key tool for concrete compaction when project conditions make internal vibration unfeasible. Understanding their applications, configurations, and best practices helps optimize results and ensures high-quality structures. At ENAR, we continue to develop technical solutions tailored to the real needs of the construction industry.

Visit our website: www.enargroup.com

Related News

.webp)

.jpg)

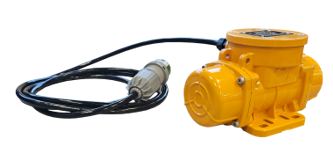

VET / VEM

External Vibrator

VET / VEM

External Vibrator

VEAF

High-Frequency External Vibrator

VEAF

High-Frequency External Vibrator